TECHNICAL SPECIFICATIONS

|

| Model |

Gross Volume approx. |

Working Volume approx. |

Power |

| RM-10 |

10 Liters |

5 Liters |

0.5 H.P. |

| RM-50 |

50 Liters |

20 Liters |

1 H.P. |

| RM-75 |

75 Liters |

50 Liters |

1 H.P. |

| RM-150 |

150 Liters |

100 Liters |

2 H.P. |

| RM-250 |

250 Liters |

150 Liters |

3 H.P. |

| RM-450 |

450 Liters |

300 Liters |

5 H.P. |

| RM-600 |

600 Liters |

450 Liters |

7.5 H.P. |

| RM-1100 |

1100 Liters |

750 Liters |

10 H.P. |

| RM-1500 |

1500 Liters |

1000 Liters |

12.5 H.P. |

| RM-2000 |

2000 Liters |

1250 Liters |

15 H.P. |

| RM-3000 |

3000 Liters |

1875 Liters |

20 H.P. |

| RM-5000 |

5000 Liters |

3000 Liters |

25 H.P. |

| RM-10000 |

10000 Liters |

6000 Liters |

40 H.P. |

A ribbon blender is an essential industrial mixing machine widely used in industries such as pharmaceuticals, food processing, chemicals, cosmetics, and agriculture. Designed for efficiency and uniformity, these blenders are perfect for blending powders, granules, and other bulk materials. Whether your requirement is for a compact 10-liter unit or a large-scale 10,000-liter blender, a ribbon blender offers versatility and reliability.

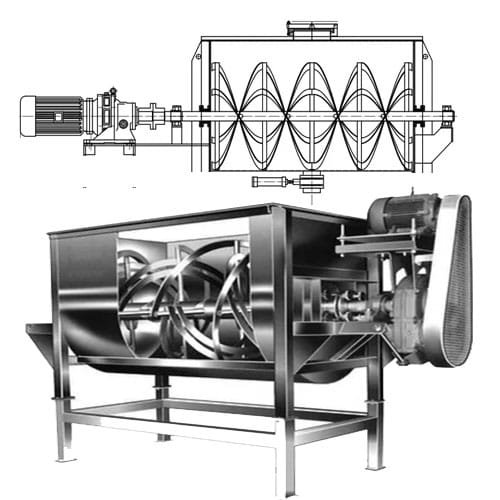

What is a Ribbon Blender?

A ribbon blender consists of a U-shaped horizontal trough and a double helical ribbon agitator. The agitator’s inner and outer ribbons rotate in opposite directions, creating a balanced movement of materials within the trough. This ensures thorough and uniform mixing of ingredients.

Key Features of Ribbon Blenders

- Capacity Range: Available in capacities ranging from 10 liters for small-scale operations to 10,000 liters for industrial-scale applications.

- Material Construction: Manufactured in stainless steel (SS304, SS316) or mild steel, ensuring durability and compliance with industry standards.

- Efficient Mixing: The dual ribbon design ensures homogeneity in mixing, even for materials with different particle sizes or densities.

- Customizable Options: Customizable features include heating/cooling jackets, spray nozzles for liquid addition, and vacuum capability for specialized mixing.

- Easy Cleaning and Maintenance: Designed with accessible openings for easy cleaning and maintenance, ensuring compliance with hygiene standards.

- Motor and Drive System: Equipped with robust motors and gearboxes tailored to the blender’s size and load requirements.

Applications of Ribbon Blenders

- Pharmaceutical Industry: Blending powders for tablets, capsules, and other pharmaceutical formulations.

- Food Processing: Mixing flour, spices, baking ingredients, and other food products.

- Chemical Industry: Homogenizing fertilizers, pesticides, detergents, and other chemical compounds.

- Cosmetic Industry: Preparing creams, powders, and cosmetic formulations.

- Agriculture: Mixing animal feed, seeds, and soil amendments.

Advantages of Ribbon Blenders

- High Efficiency: Ribbon blenders ensure quick and thorough mixing, reducing processing time.

- Cost-Effective: A single unit can handle a variety of mixing applications, minimizing the need for multiple machines.

- Scalability: Available in a wide range of capacities to meet varying production demands.

- Ease of Operation: Simple design and user-friendly controls make it easy to operate and maintain.

- Durability: Built with high-quality materials for long-term use, even in demanding industrial environments.

Choosing the Right Ribbon Blender

When selecting a ribbon blender, consider the following factors:

- Capacity Requirements: Determine the volume of material to be mixed per batch.

- Material Properties: Consider the density, viscosity, and particle size of the materials to be blended.

- Customization Needs: Identify additional features like heating, cooling, or vacuum systems based on your application.

- Compliance Standards: Ensure the blender meets regulatory requirements, especially for pharmaceutical or food-grade applications.

Maintenance Tips for Ribbon Blenders

- Regular Inspection: Check for wear and tear on the agitator ribbons and trough.

- Lubrication: Maintain proper lubrication of the motor and gear system.

- Cleaning: Clean the blender thoroughly after each use to prevent cross-contamination.

- Alignment Checks: Ensure the agitator and motor are properly aligned to avoid mechanical issues.

Why Choose JSK Engitech Industries for Ribbon Blenders?

At JSK Engitech Industries, we specialize in manufacturing high-quality ribbon blenders tailored to your specific needs. With capacities ranging from 10 liters to 10,000 liters, our machines are designed for optimal performance, durability, and ease of use. We prioritize customer satisfaction by offering customizable solutions and unparalleled after-sales support.

A ribbon blender is a versatile and efficient solution for mixing bulk materials across various industries. With its scalable capacity range from 10 liters to 10,000 liters, it meets the diverse needs of small-scale and large-scale operations alike. Choosing the right blender and maintaining it properly ensures consistent performance and long-term reliability. Trust JSK Engitech Industries to provide you with the best-in-class ribbon blenders for all your mixing needs.